Difference between revisions of "Machinery Setup"

| Line 71: | Line 71: | ||

'''6. Enter an estimate of the total amount spent on repairs and maintenance over the implement’s productive life.''' | '''6. Enter an estimate of the total amount spent on repairs and maintenance over the implement’s productive life.''' | ||

* For example, | * For example, if you were to replace the discs of your Offsets (28 plate) three times ($100/disc x 28 discs x 3 sets = $8,400) and spend $100 each year on general maintenance over the 15-year life ($1,500) then the total amount to be entered would be $9,900. | ||

Revision as of 23:24, 8 November 2023

This page can be used to edit existing information for tractors and implements or to add additional information to calculate machinery costs. It is likely that most of this page is filled out already if data has been entered on the Cane Growing Costs or Other Crops Growing Costs pages.

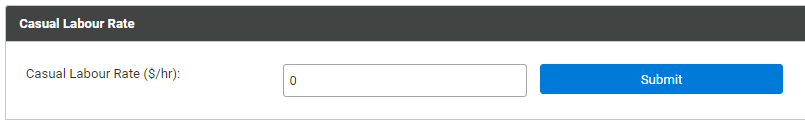

Casual Labour Rate

Enter the casual labour rate, if applicable, in dollars per hour ($/hr) and click "Submit".

- Please note that labour can be also added as a fixed cost on the Fixed Costs page.

- Only include labour once in either the casual labour rate section or as a fixed cost.

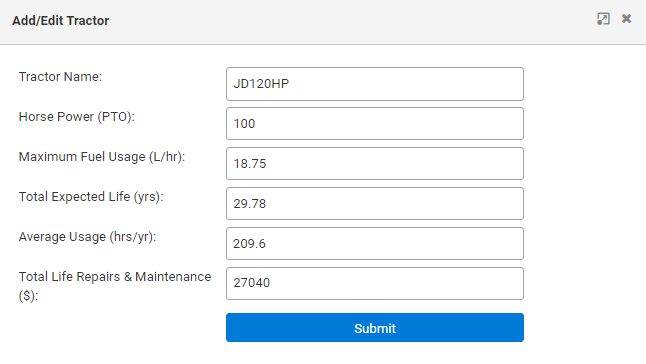

Tractor Costs

Add Tractor Costs by clicking the "Add Tractor" button then:

1. Enter a name for the tractor. For example, JD 120HP.

2. Enter tractor horsepower (PTO). For example, 100 PTO.

- PTO HP is used because it is involved in the calculation of expected maximum fuel usage, and the PTO HP is roughly 80% - 90% of gross engine HP in many cases.

- The calculated expected fuel use in litres/hour (L/hr), based on tractor horsepower (PTO), will be displayed. This is the maximum fuel use when the tractor is performing at maximum load. The figure can be changed if required.

3. Enter an estimate of the tractor’s expected productive life in years. For example, 30 years.

4. Enter the number of hours per year the tractor is used (hrs/yr). For example, 210 hours per year.

5. Estimate the total amount spent on repairs and maintenance (R&M) over the tractor’s productive life. For example, R&M costs may incorporate costs for servicing (e.g. oil and filters), tyre replacements and other minor and major repairs (e.g. electrics, hydraulics, GPS) over the life of the tractor.

For a (hypothetical) total of $27,040 you would add together:

- Servicing costs of $10,000 (servicing every 250 hours at a cost of $250 per service over the lifetime of approx. 10,000 hours).

- Tyre costs of $10,000 (tyres might be replaced twice over its life, $1,250 x 4 tyres x 2 sets = $10,000).

- Repair costs of $7,040.

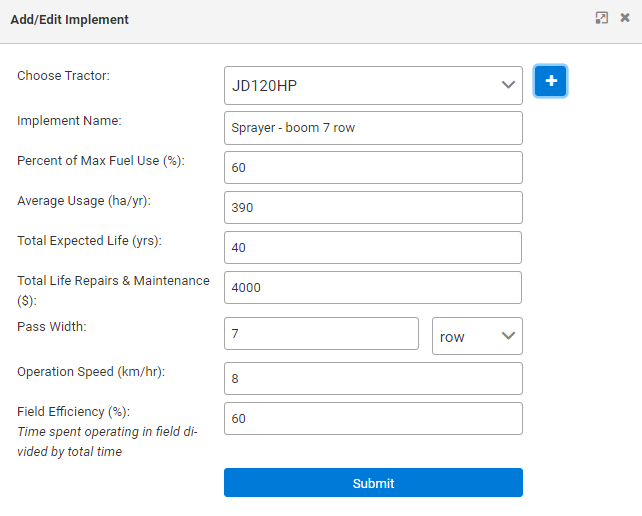

Implement Costs

Implement information can be entered once at least one tractor has been added. Add implement costs by clicking "Add Implement" and then:

1. Choose the associated tractor from the drop down list or click the plus icon to add a tractor. Each implement is assigned to one tractor.

2. Enter the name of the implement. For example, Offset discs 28 plate.

- Implement percentage of full load, speed and field efficiency is influenced by the type of operation (i.e. tilling, spraying, planting etc) and soil type.

3. Enter an estimate of how hard the tractor is typically working when the implement is being used as a percentage of full load (%). This will automatically calculate the amount of fuel used compared to maximum consumption.

- For example, rotary hoeing heavy ground may require the full power of a 180HP tractor so 100% should be entered, while boom spraying may only require a 120HP tractor to operate at half power so 50% should be entered.

- Another example is, if an operation uses 8L/hr and a tractor’s maximum fuel use is 10L/hr, then the percentage of full load is 80%.

4. Enter the number of hectares per year the implement is operated across. This figure along with the tractor’s expected productive life in years determines the implements hours per year based on implement work rate.

- Offset discs might be used across 25ha of fallow paddocks twice so 50ha should be entered, while a sprayer with tracking legs might be used once in 25ha of plant cane and twice in ratoons (4 ratoons, 25ha each) so 225ha should be entered.

5. Enter the expected productive life of the implement in years. For example, 40 years.

- FEAT allows you to specify lifetime tractor hours and include the area that an implement covers each year (which determines the implement’s hours per year based on implement work rate). After you have specified tractor and implement R&M, FEAT then calculates a combined (tractor and implement) hourly R&M cost.

- Please note that R&M costs vary between farming enterprises and these values should be customised for your own situation.

6. Enter an estimate of the total amount spent on repairs and maintenance over the implement’s productive life.

- For example, if you were to replace the discs of your Offsets (28 plate) three times ($100/disc x 28 discs x 3 sets = $8,400) and spend $100 each year on general maintenance over the 15-year life ($1,500) then the total amount to be entered would be $9,900.

Work rate parameters (width of pass, speed, and field efficiency) are included for each grower-performed operation in the FEAT file:

7. Enter the width of the implement’s pass or swath width. A 3-row stool splitter might have a 5.4 metre width of pass, which could be entered as 5.4m or 3 rows (if row width has been entered as 1.8m on the Scenario Assumptions page).

8. Enter the speed the implement is typically operated at down the drill (km/hr). For example, 8 km/hr.

9. Enter an estimate of the implement’s field efficiency. Field efficiency is a ratio of the time spent actually using an implement relative to the total time spent in the tractor.

- Field efficiency is influenced by; time taken to perform adjustments to machinery, time to add seed/fertiliser, minor breakdowns, turning at row ends and other non-productive delays.

- For example, when ripping most time is spent ripping in the paddock (90secs/row) plus some time spent turning at the end of each row (22 sec/row). Field efficiency in this scenario is 80%, which is calculated by dividing 90 secs by 112 secs (90 secs+22secs).

- Chemical application is likely to have lower field efficiency than tilling due to additional time spent refilling tanks.

- You can evaluate the accuracy of field efficiency by cross-checking with the implied work rate (ha/hour – shown after clicking the "Submit" button).

Tractors and Implements Table

All tractors and implements in a scenario are shown in this table.

- Click on the tractor name if you wish to show the implements underneath that tractor and click again to just show the tractor again.

- If you wish to delete tractors or implements, you must first delete all instances of them in the Cane Growing Costs and Other Crops Growing Costs pages.